CASE STUDY

PRODUCT QUALIFICATION TEST (PQT)

FOR SUBMERGED HIGH TEMPERATURE PIPELINE

SubSea & Splash Zone Coatings

Project Data

| Location | Kuantan, Pahang, Malaysia |

| Distributor | PluPerfect Technology Sdn Bhd |

| Products | Viscowrap™ XHT, PE Compression Wrap, Denso™ Glass Outerwrap and Denso™ Rockmesh 6mm |

| Date | February 2024 |

Project Details

One of the major oil and gas operators in Malaysia is laying new offshore pipelines in Malaysia. The work will involve offshore installation using a heavy lift and pipelaying vessel.

Together with our local distributor, PluPerfect Technology, Denso won the work scope for Field Joint Coating application with a global offshore installation contractor.

The proposed system, combines the use of Viscowrap™ XHT, PE Compression Wrap, Denso™ Glass Outerwrap and Denso™ Rockmesh 6mm. It has undergone all of the ISO 21809-3 testing, which qualifies the use of the system up to 115°C, even though the project requirement is 109°C.

As part of the qualification and application training, Denso worked with the local distributor to provide training for 24 personnel and a further Product Qualification Test (PQT) was conducted successfully in the presence of the end client.

Training 24 personelle to apply the Denso system for the submerged high temperature pipeline.

Personelle applying PE compression wrap over Viscowrap XHT during training.

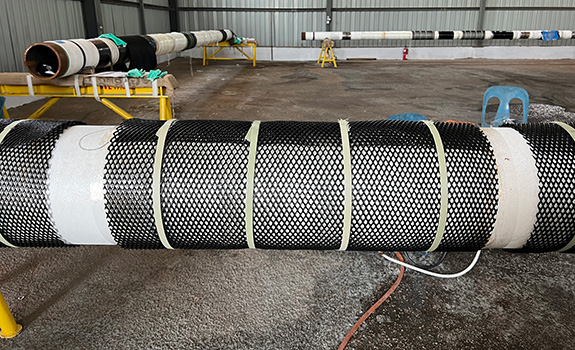

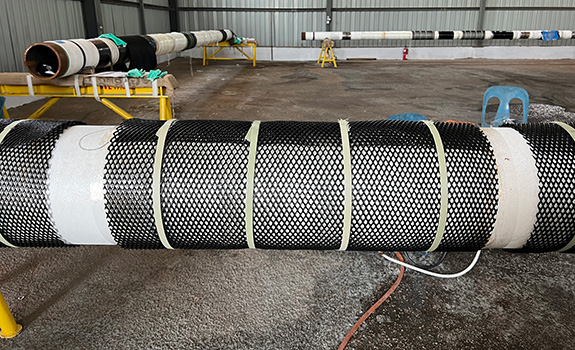

Completed Denso system for the submerged high temperature pipeline.

Lengths of pipe completed with the Denso system.

Training 24 personelle to apply the Denso system for the submerged high temperature pipeline.

Personelle applying PE compression wrap over Viscowrap XHT during training.

Completed Denso system for the submerged high temperature pipeline.